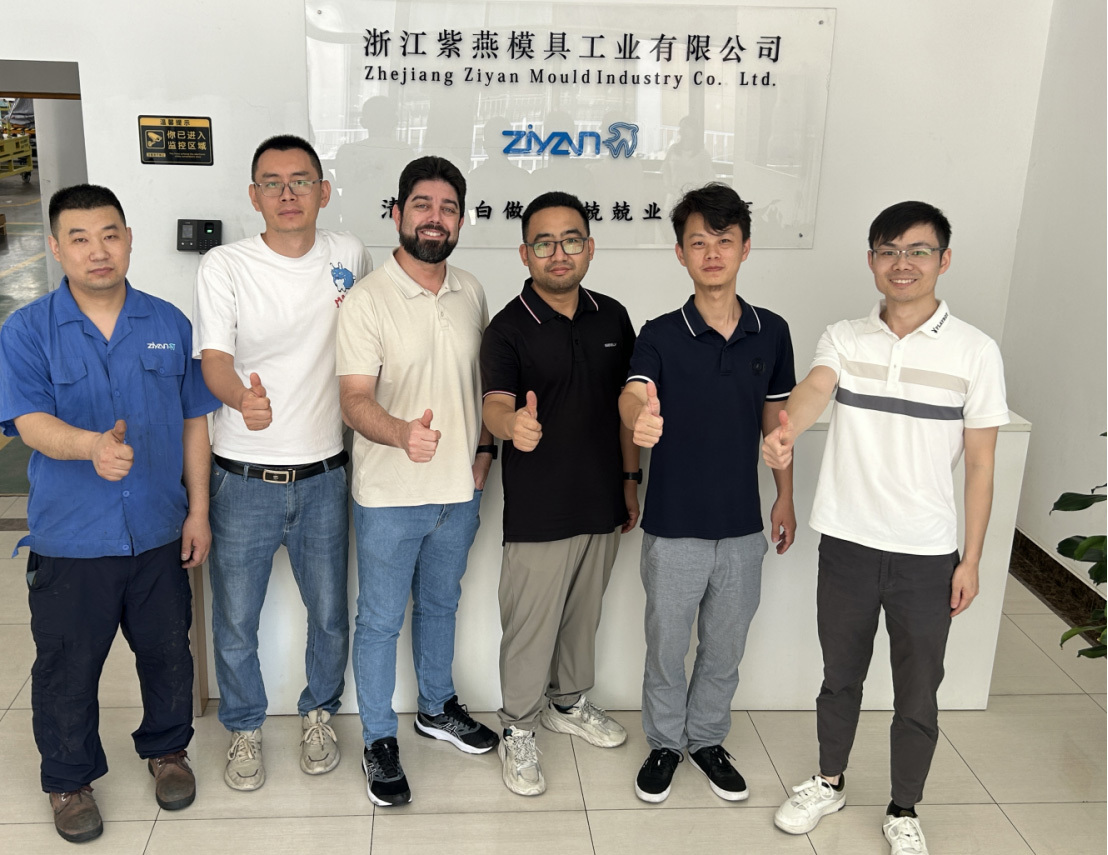

Recently, Ziyan Mould dispatched a customer service team to successfully complete the installation and debugging of checking fixtures at the Renault automobile plant in Brazil. The successful completion of this task further solidifies the close cooperative relationship with the globally renowned automaker Renault.

2026/01/13

Thirty years of hard work, a new journey of innovation: Ziyan Mould celebrates its 30th anniversary

On December 26, 2025, Ziyan Mould Industry Co., Ltd. celebrated its 30th anniversary. General Manager Mr. Luo Xiaojin and many long-time employees gathered to reminisce about the company's entrepreneurial journey and look forward to future development through warm and solemn activities such as group photos and a tea party.

2025/12/26

Ziyan Mould 2025 Team Building Activity Successfully Held

Ziyan Mould Industry Co., Ltd. organized a team-building trip for all employees from November 5th to 9th to the picturesque cities of Yixing, Liyang, and Xitang.

2025/11/12

Recently, a team from Zhejiang Ziyan Mold Industrial Co., Ltd. traveled to Morocco, and successfully completed the on-site commissioning and acceptance of a high-precision checking fixture at the Stellantis Group's local factory. This marks a significant step forward for Ziyan Mold in its international collaboration and technical services.

2025/10/22

Ziyan Successful Partnerships with Geely and Renault Brazil Through Checking Fixture Project

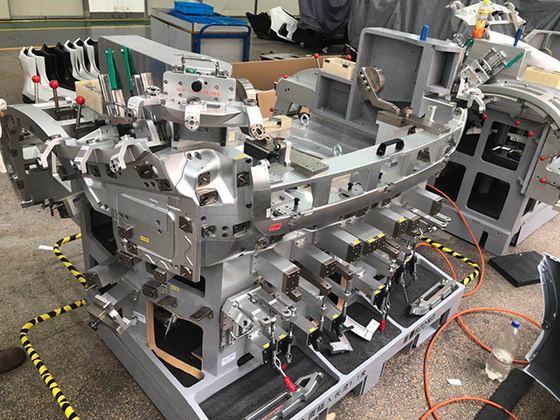

Jiaxing, China – [2025.9.25] – Ziyan Mould, a specialized manufacturer of high-precision automotive checking fixtures, recent projects with Geely Auto and Renault Brazil have undergone comprehensive evaluation and acceptance and are about to be shipped.

2025/09/26

What is a car checking fixture?

Automobile checking fixture, a tool tailored for the automotive industry, is designed to comprehensively detect various parameters of automotive parts and vehicles, covering size, shape, position and function, so as to ensure that each product can accurately meet the design requirements. Its wide application is reflected in many links: from mold precision measurement and adjustment in the production preparation stage to daily size management after mass production, automotive checking fixture plays an indispensable role. It can meticulously check every part of the car, including key components such as the body, door, engine, etc., to ensure that the size and size of each component strictly meet the design standards, thereby improving manufacturing efficiency and quality. At the same time, automotive checking fixture is also a strong guarantee for quality control, ensuring that every car can meet the expectations of consumers with high standards and strict requirements.

2025/03/28

What are the functions of a car checking fixture?

The automobile checking fixture plays a significant role in the entire process of automobile production, covering multiple links from design to mass production. In the product design stage, it can help new models to quickly debug and serve as a reference benchmark; in the production preparation stage, it can measure and adjust the mold accuracy and perform daily size management; in the product verification stage, it can carry out design confirmation work; in the trial production stage, it can determine the root cause of the conflict problem and guide the modification of unqualified parts; in the mass production stage, it is used for daily quality control and problem analysis to fully guarantee the quality of automobile products.

2024/02/21

What materials are used to make car checking fixtures?

The materials used to make automotive checking fixtures are diverse, including aluminum, resin, iron, carbon fiber, silicone, etc. Aluminum has high strength and corrosion resistance, resin has good elasticity and wear resistance, and iron also has its applicable scenarios; carbon fiber can increase strength and rigidity, and silicone is used in specific expansion joints. Different materials have their own characteristics, and manufacturers need to weigh and select appropriate materials based on the specific application scenarios, usage environment and needs of the checking fixture.

2025/03/28

What is the car checking fixture used for?

1. Automobile checking fixture is developed according to the special planning and design requirements of each model. Professional automobile checking fixture can be used to check its size and size, and then measure and evaluate. It is mainly used for the determination and adjustment of mold accuracy in the production preparation stage and the daily management of dimensions after mass production.

2025/03/28